The Sand mold was chosen as a mold material, and prediction analysis has been implemented using computer-aided simulation software. Medium carbon steel was chosen for its wide variety of automotive applications. Using Procast Simulation software, mold filling, and solidification analysis was performed. The spatial patterns in electronic fluid flow and magneto-hydrodynamics reveal hexagonal structures coaligned to the crystal lattice and quasiparticle bound states 14, as long anticipated 15,16,17.

Jmatpro fluid flow software#

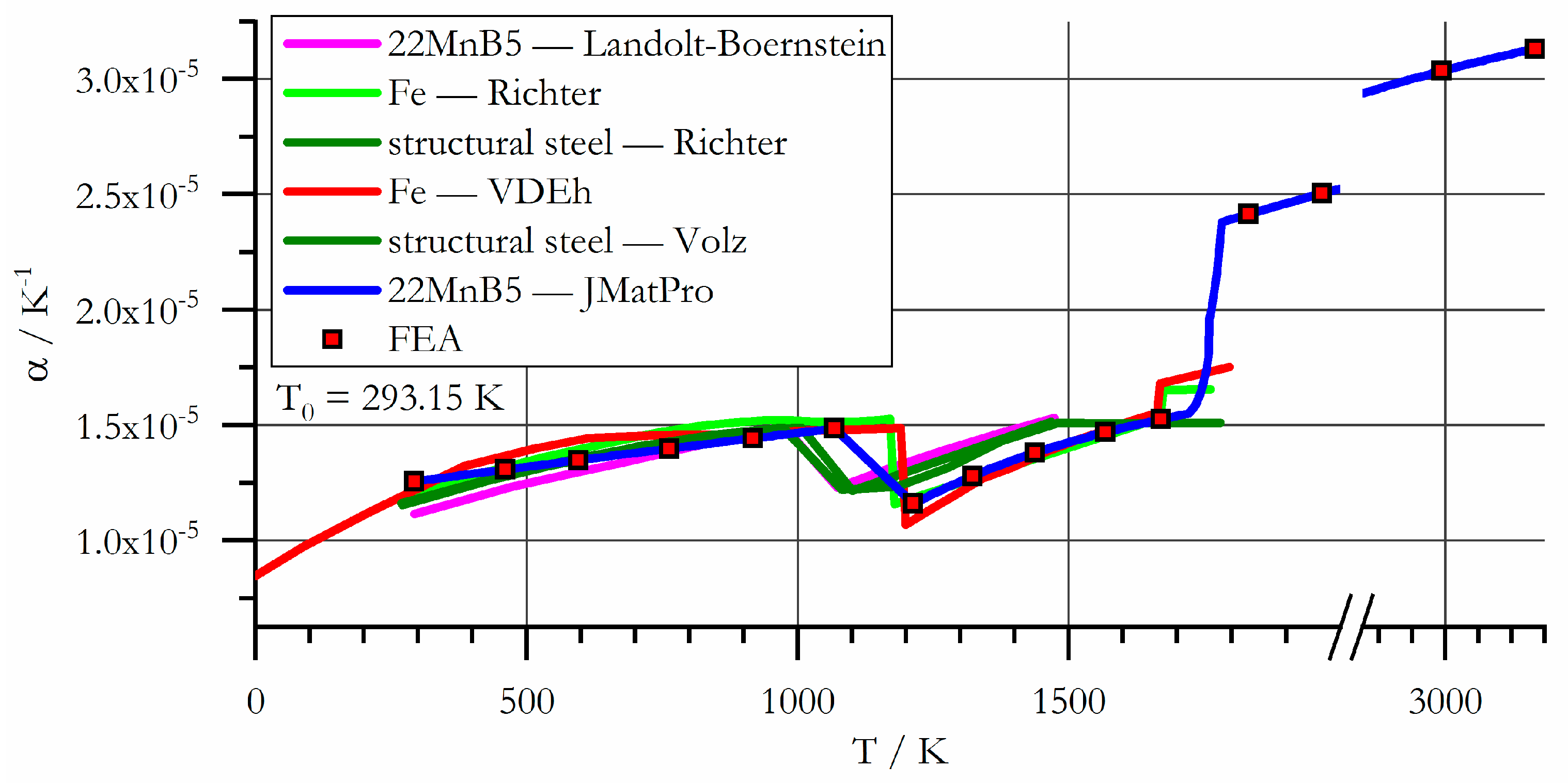

In this work, creo software was used to create the Solid model of a pulley and the gating system. Various researchers have stated that 90% of casting defects are accumulated only because of the deficient design of the gating and feeding systems. Fluid Plan/ THERMCAL icepak4.3 Flomerics flotherm 7.0(CFD) Fluent Icepak v4.3CFD QSR NVivo 7. JMatPro JMatPro can be used to predict mechanical properties, phase fractions, dendrite size with cooling curves along with many other physical properties for a given chemistry such as conductivity, density, specific heat, etc. Knowledge of casting defects and causes is essential for quality control. The pulley’s quality characteristics have been affected by casting defects, which leads to a large number of shop floor trails, a high rejection rate, and poor casting performance. The critical issue with the sand casting process is casting defects and unstable casting quality. Read more about these Metal Processing Module updates below.

Sand casting is one of the commonly utilized metal casting processes because of its inherent benefit of the production, low cost, and high production rate. For users of the Metal Processing Module, COMSOL Multiphysics ® version 5.6 brings a physics interface for carburization, import functionality for material properties, and enhanced capabilities for modeling phase transformations. Casting is the method by which different kinds of metal products are manufactured. Flow-3D cast have a limited database for aluminium, steel, zinc, magnesium and iron, however, it offers material properties from JMATPRO at very nominal cost.

0 kommentar(er)

0 kommentar(er)